Fineness of cement

Definition of cement fineness

The fineness of cement is a measure of the size of cement particles and is expressed in terms of specific surface area of cement.

As you may know, the final process of cement manufacturing is to grind clinker mixed with gypsum. When cement reacts with water, the available area for reaction is the total surface area of cement. Thus, the rate of hydration depends on the fineness of the cement particles. The higher the fineness, the higher the rate of hydration and heat evolution is.

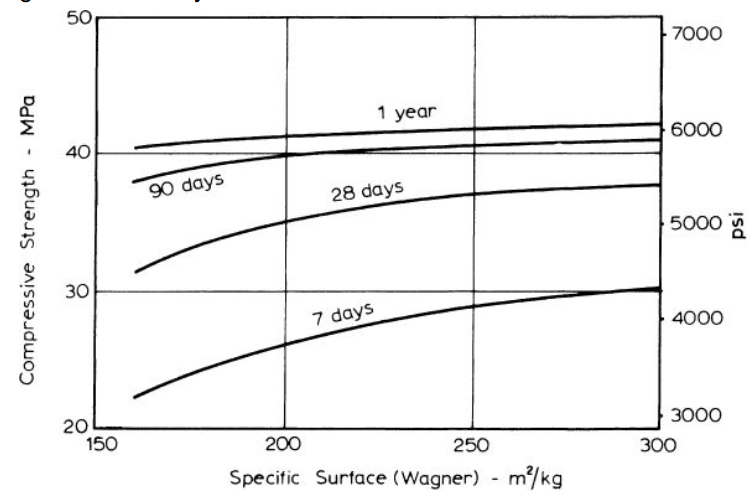

Note that fineness affects only the early age strength which means the final strength will be the same. Look at the below figure and you will find that the late-age strength for same cements having different fineness is almost the same for all of them.

Negative Effects that Fineness may Cause

- Increasing the fineness of cement will affect the cost of grinding negatively which means the higher the fineness is, the higher the most production is.

- Also, finer cement deteriorates more quickly when exposed to the atmosphere.

- Finer cements are more effective and causes more severe deterioration in case of alkali-reactive aggregate.

- Increasing the fineness raises the potential for shrinkage cracking.

- We need more gypsum for finer cements to properly control the setting time of cement because more C3A is available for early hydration.

- The water content of a paste of standard consistency is greater the finer the cement.

- As you see, fineness is a vital property of cement and has to be carefully controlled to obtain the desired properties of cement.

Testing for Fineness of cement

The current test methods for fineness gives a value expressed as the total surface area in square metres per kilogram. The basis method for calculation of particle size distribution is sedimentation or elutriation. These methods stand on the idea that the rate of free fall of particles depends on their diameter.

Methods for testing fineness

The current existing methods in the ACI to determine cement fineness are:

ASTM C 115: Fineness of Portland Cement by the Turbidimeter

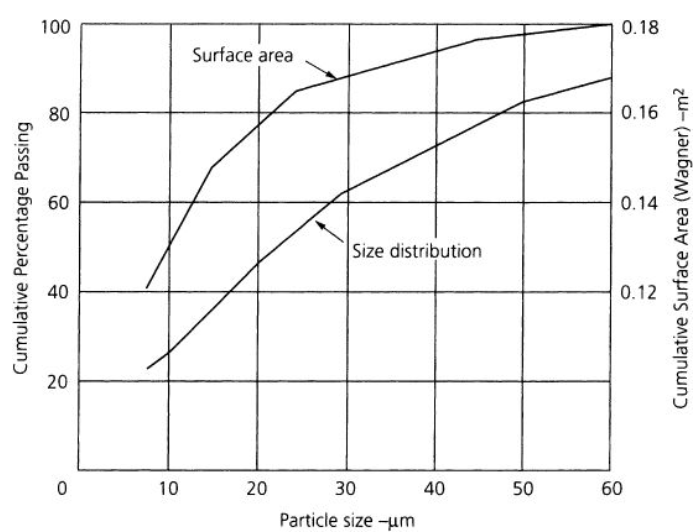

In this test, a light beam is used to measure the concentration of particles in suspension in kerosene at a specific level, with a photocell used to quantify the amount of light that is transmitted. Figure 2 shows a typical curve of particle size distribution which gives also the corresponding contribution of these particles to the total surface area of the sample.

ASTM C 184: Fineness of Hydraulic Cement by the 150-mm (No.100) and 75-mm (No. 200) Sieves

This test method covers determination of the fineness of hydraulic cement by means of the 150-µm (No. 100) and 75-µm (No. 200)

ASTM C 204: Fineness of Hydraulic Cement by Air-Permeability Apparatus

Using a device created by Blaine, the air permeability method may also be used to estimate the specific surface of cement. The approach is based on the relationship between the surface area of the particles that make up a granular bed and the flow of a fluid through the bed. This means that the permeability of a bed with a particular porosity, or one in which the entire volume of the bed contains a defined volume of pores, may be linked to the surface area per unit mass of the bed material.

The mass needed to create a bed with a porosity of 0.475 and a thickness of 10 mm may be determined since we know the density of cement. A manometer attached to the top and bottom of the cement bed measures the pressure drop that results from passing a stream of dry air through the cement bed at a constant speed. This amount of cement is placed within a cylindrical container. A flowmeter that consists of a capillary that is inserted in the circuit and a manometer that is positioned across both of its ends measures the rate of airflow.

ASTM C 430: Fineness of Hydraulic Cement by the 45-mm (No. 325) Sieve

This test method covers the determination of the fineness of hydraulic cement by means of the 45-μm (No. 325) sieve.

Read Also: