What is Compressive Strength of Concrete?

The compressive strength test is the most crucial of the several tests conducted on the concrete since it provides information about the properties of the concrete.

Compressive strength can be defined as the capacity of concrete to withstand loads before failure.

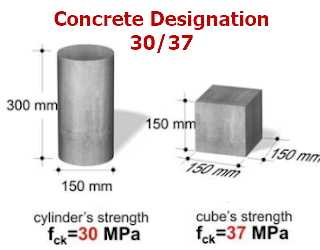

Compressive Strength of Concrete Cube vs Cylinder

In testing concrete for compressive strength, the shape of specimen may differ depending on you location and the code you are working according to.

The shape of the specimen can be a cylinder or a cube. So, what is the difference between the two cases?

Do you expect the shape of specimen to affect the value of the strength even if they may have the same mixture design?

The answer is Yes!

The compressive strength of a cube is larger than the compressive strength of a cylinder for specimens prepared from the same mixture design.

Why is Cube strength larger than Cylinder Strength?

The primary cause responsible for this variation is the different length to diameter ratios for cubes and cylinders.

For the previous image, the length to diameter ratio for cube is 1:1, while for cylinders, the ratio is 2:1. That is why cubes are stronger.

In addition, the compressive testing machine’s top platen has greater surface area to interface with the cube than the cylinder, increasing confinement to the cube specimen.

Thus, because there is more confinement for the cubes by platens of the compressive testing machine, the cube sample will require higher stress to fail compared to the cylinder.

Before the specimen (a cube or cylinder) is loaded, the steel plates are positioned above and below the specimen. In contrast to the concrete specimen, there is no lateral expansion at all in the steel plates. This implies that the steel will prevent concrete from expanding laterally as a result. Thus steel platens will prevent the concrete specimen from expanding laterally. This is a common occurrence in the specimen’s concrete structure, which is located close to the plate’s end. As a result, in addition to the compressive stress brought on by the imposed compressive force, frictional tension develops between the plate and the specimen..

Read Also: Mechanisms of Concrete Confinement

As a result, an element inside the specimen will experience “shear stress”. This is as a result of two acting stresses on the specimens.

- Friction stress between the steel plates and concrete specimens.

- Compressive force on the specimens.

It has been noted that the interaction of Stresses 1 and 2 will cause an axial load failure. A greater compressive strength number will be provided as a result of this.

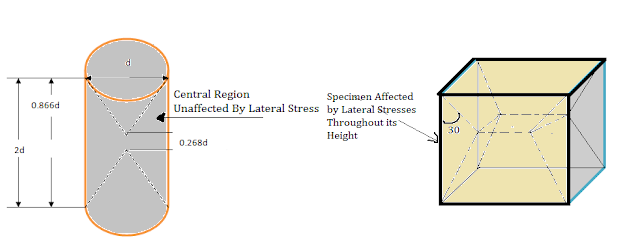

Look at the below figure.

It has been noted that the cube’s overall height is affected by the restraint caused by friction between the specimen and the platens. The cylinder, on the other hand, has unaffected parts in this situation. The cubes and cylinders fail by shearing at 45 and 60 degrees, respectively, from the horizontal.

As a result, it is obvious that the cube specimen will experience greater overall stress than the cylinder specimen. Even with the same concrete mix, this will lead to a higher compressive strength in cubes than in cylinders.

There is an equation that approximately governs the relationship between the cube and cylinder strengths, which is as follows:

Compressive Strength of Cube = 1.25 x (Compressive Strength of Cylinder)

As long as the mixture design is the same for both specimens.