capacity of concrete to withstand loads before failure.

In all standards, the characteristic strength of concrete is determined at 28 days. In this article, we discuss why standards chose 28 days after casting as the reference day for testing compressive strength.

Strength Gain of Concrete

Concrete is an artificial conglomerate stone made essentially of Portland cement, water, and aggregates.

When first mixed the water and cement constitute a paste which surrounds all the individual pieces of aggregate to make a plastic mixture.

A chemical reaction called hydration takes place between the water and cement, and concrete normally changes from a plastic to a solid state in about 2 hours.

So, why 28 days for testing the compressive strength of concrete?

Theoretically, if a source of moisture exists for concrete, it will continue to gain strength forever. However, this does not actually happen in reality.

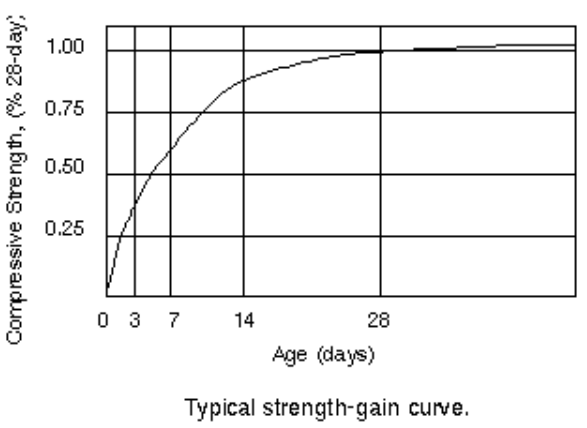

To understand the reason why standards chose 28 days for testing compressive strength, let us look at the development of concrete strength:

As you can, concrete starts to gain strength at a high rate and then at later age (beyond 28 days), the rate of strength gain becomes very slow.

The following table shows the value of strength gain assuming the maximum value of strength is 100% at various ages:

| Age (days) | Strength (%) |

| 3 | 37% |

| 7 | 62% |

| 14 | 83% |

| 28 | 99% |

Therefore, concrete will gain above 90% of its strength in the first 28 days. There is no need to wait beyond 28 days for the remaining strength gain. This is impractical.

Due to this, the industry embraced the 28-day strength as a standard, and specifications frequently include reference to compression tests of concrete cylinders or cubes that are crushed 28 days after being made.

Summary

It is evident that concrete strengthens quickly in the first few days following casting—83 percent in only 14 days. Concrete continues to grow strength even after it reaches a strength of above 90 percent in 28 days, but the rate of increase in compressive strength is much slower than it was in the first 28 days.

Since the concrete strength at 28 days is 99 percent, it is nearly at its maximum strength. As a consequence, we depend on the results of the compressive strength test at 28 days and utilize this strength as the foundation for our design and evaluation.

Read Also:

How to Prepare Cube Samples from Fresh Concrete?