Ductility is a very important aspect to look for when designing a structure, especially for lateral load. But, what is ductility?

According to the book, ductility is defined as:

the ability of reinforced concrete members to undergo considerable deflection prior to failure.

Basically, this means that ductility is simply a way to measure of the ability of concrete (actually, it can be any material concrete, steel, wood, any materials has its own ductility) to resist deformation when subjected to load.

Each material has a certain level of ductility. Some have none and some have a lot.

Imagine having a ruler. If it is made of flexible plastic and you bend it, it will bend and develop some stretch marks before it breaks. What if it was made of rigid plastic? It will bend slightly and break suddenly when it gets bent beyond a certain point (its deformation limit).

Thus, we would like to have our buildings ductile above a minimum limit. This ductility will provide sufficient warning before any failure happens (like the stretch marks for the ruler). In reinforced concrete buildings appear in the form of cracks. These warnings provide enough time for any remedial actions such as repair/strengthening or even evacuation of residents in extreme cases.

This is very important in general and in seismic areas, especially.

This article has a purpose of indicating few measures that can improve the ductility of reinforced concrete members.

Improving the Ductility of Reinforced Concrete Elements

- If possible, keep the structural system for load transferring as simple as you can. Do not seek complexity unless there are constraints that push you to do that. Regular and uniform systems are preferable.

- In case of lateral load resisting systems such as the reinforced concrete moments frames, it is recommended to increase the redundancy of the system.

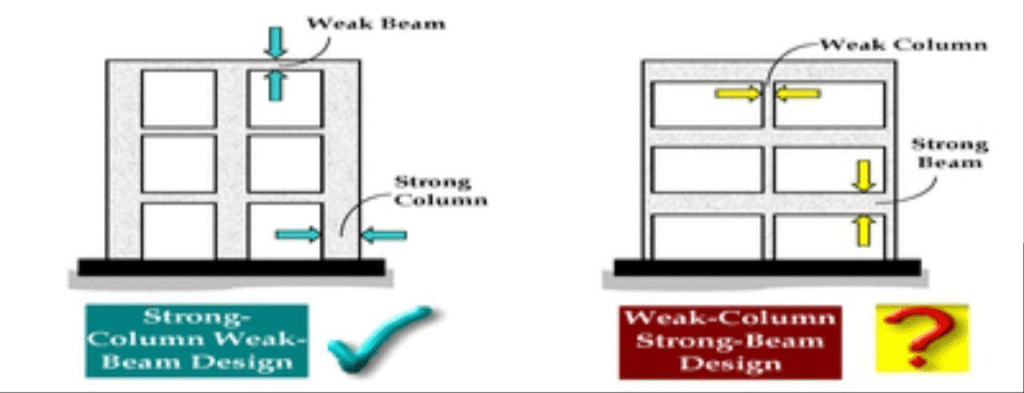

- Another important aspect is the implementation of the concept of “weak beam – strong column” in the structural design process to prevent the column failure in case of extreme loading or to prevent the formation of plastic hinges in columns. As the name suggests, the beams should fail before the columns (or create plastic hinges). The columns and beams must be constructed in accordance with the Strong-Column Weak Beam Design in order to prevent the progressive collapse of a structure caused by the cascade effect caused by column failure at the lower levels. These plastic hinges produced in the beams enhance the structure’s ductility, which allows it to withstand huge lateral displacements while still dissipating seismic energy more effectively and preventing catastrophic collapse.

- Of course, the sudden and brittle types of failures should be avoided such as shear failure and concrete compression failure.

- Eliminating the risks of foundation system failure is another thing to keep in mind when seeking improvement in ductility .

- When choosing between under-reinforced concrete sections and over-reinforced concrete sections, always select the under-reinforced concrete sections when there are no restraints. Under-reinforced concrete sections has better ability to deform significantly before failure.

- One last point to mention is the use lateral confinement at critical locations such as connections and important locations in columns to increase the capacity of these locations to withstand deformations.

Employing the appropriate parts of the relevant codes, such as material requirements for ductility, ductile detailing of beams, columns, and frames, and employing suitable detailing for reinforcements at joints, the aforementioned actions can be carried out.

Improving the Ductility of Reinforced Concrete Elements

Read Also: