Before we jump in and disucuss ferrocment materials, you may want to have a general idea of what is ferrocement, its applications, advantages, etc in this post here.

This post deals with the materials used to develop ferrocement giving an insight on what is included in a ferrocement mix and its properties.

Ferrocement Materials

A Ferrocement mix includes four componenets:

- a portland cement mortar matrix

- reinforcement

- admixtures

- coatings

Mortar Matrix

The mortar matrix for application in ferrocement composes of hydraulic cement (a cement that is capable of hardening under water, according to merriam-webster) and inert filler material.

The ordinarly portland cement is generally employed, sometimes blended with a pozzolanic material. A well-graded sand [passing seive size of 2.36 mm (No. 8)] is usually the inert filler material for mixing with the cement. In some cases depending on the properties of the reinforcing mesh (space between bars and distribution), we may use a mortar with small-size gravel.

The chemical properties and composition of cement, the type of sand, the water-to-cement ratio (abbreviated as w/c) , and the curing conditions of the final product (e.g. using water spray, curing compound, etc.) all affect the physical characteristics and microstructure of mortar. Naturally, the mortar matrix makes up a 95% of the volume of ferrocement. This is why the quality of the mortar greatly influences the end properties of ferrocment and care has to be given to its development).

Research showed that the used of portland cement in ferrocement mixture yields a composite matrix with some tensile strength. In contrast to regular reinforced concrete, it appears that the composite activity between the matrix and the reinforcement is more prominent in ferrocement. The tensile characteristics of the final matrix will also be impacted by whether fibers are used and the choice of fibers.

The ability of the matrix to withstand tensile stresses and the reistance to cracking are both positively impacted by the addition of short, discrete fibers of various types. In order to effectively produce ferrocement, relatively short and slender (L/d = 100) steel fibers may be dispersed at random in hydraulic cement mortars. This will increase the tensile strength and improve the shear resistance of the mortars as a whole, affecting the design of the material system and the final properties of the produced ferrocement product. Ferrocement made with fiber-reinforced mortar usually has much larger mesh opening and spacing compared to conventional ferrocement.

Now coming to the water used to make the mortar matrix. The water used should be potable and relatively free from organic matter. Water-cement ratios for producing ferrocement vary between 0.30 – 0.55.

A workable mix will typically completely penetrate and encircle the mesh reinforcement, have appropriate levels of shrinkage, and have adequate porosity. Admixtures that lower water (water reducers and superplasticizers) can be used to increase mix plasticity.

Reinforcement

Reinforcement used for ferrocement is typically comes in the form of layers of continuous mesh manufactured from single strand filaments.

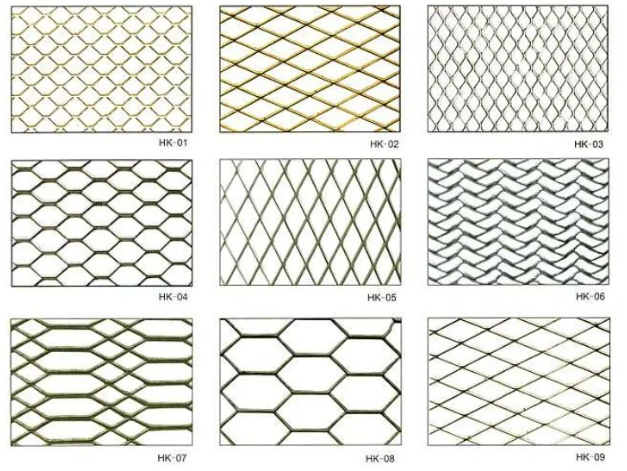

Specific mesh types include:

- Woven or interlocking mesh

- Woven cloth mesh in which filaments are interwoven without rigid connection at intersections

- Welded mesh with a rectangular pattern formed by perpendicular wires welded at intersections

- Woven patterns that may include diagonal filament woven through the rectangular mesh pattern.

The following figure shows but a few of the mesh examples.

Other types of metal reinforcement include punched or similarly perforated sheets and expanded metal lath, which is made by slicing narrow gage sheets and expanding them in a direction perpendicular to the slits. Continuous filaments that are constructed randomly, or at least irregularly, into a two-dimensional mat shape make up a different type of reinforcement. This specific type of reinforcement was created using glass fibers and organic natural fibers.

The quantities, sizes, and qualities of the materials employed, in addition to the mesh dimensions, are all quite variable. Before or while making the mesh, certain filaments are galvanically coated or impregnated with sizing. The size or gage of the filament, its strength, ductility, production, and treatment are expected to have an impact on the properties of the final ferrocement product.

Admixtures

Ferrocement can use various admixtures that are typically applied in conventional reinforced concrete such as water-reducers, superplasticizers, setting-time control admixtures, etc.. In addition to these admixtures, ferrocement may need chemical additives specifically to reduce the reaction between the matrix and galvanized reinforcement. Research showed that chromium trioxide is good in this regard with mixed with the water. Recommended solution concentration depends on the water-cement ratio used, but is approximately 300 parts per million by weight of mortar. No special precautions need be taken when using nongalvanized reinforcing materials.

Surface Coatings

Surface coatings/treatment are typically used to add a feature to concrete that makes it capable of resisting the surrounding environemnt and extend the service life of a concrete element.

Ferrocement may be treated using many of the surface coatings and impregnation techniques available for use with ordinary concrete and reinforced concrete constructions. These include the use of acrylic, latex, and cement-based coatings, as well as polymer impregnation. They are used to give a surface with a specific functional design, control surface degradation, and minimize porosity.

Matrix Mix Proportions

This section provides a brief guidelines on the mix proportion ranges of the mortar used for producing ferrocement :

- Sand to cement ratio by weight falls between 1.40 to 2.50

- Water-to-cement ratio by weight ranges betweeb 0.30 to 0.50. Water amount should achieve the requirements of consistency and compactibility.

- A sand passing a 1.16 mm (No. 16) sieve has given satisfactory results in many practical applications

Read Also: