Cold weather concreting is one of the most stubborn situations that concrete practitioners have to face every year in construction works in the fall and winter seasons in cold regions.

Larger implications of lower temperatures

With cold weather concrete pours, contractors face three main obstacles:

- Longer Initial Set Times: Concrete takes longer to first set in lower temperatures. This results in finishing teams working longer days, which raises project expenses.

- Concrete that has just been mixed freezes at -2°C, causing damage. Pours at temperatures close to or below this risk freezing before the concrete completely cures. Freezing is not permitted since it reduces the concrete’s long-term performance and durability.

- Lower Rate of Strength Development: Lower temperatures also result in a slower rate of strength gain, which prolongs the time it takes to remove protections and might increase project expenses.

Casting concrete in cold weather is a topic to be covered in a series of articles. We have got some here.

- COLD WEATHER CONCRETING: DEFINITION, ISSUES, AND PRECAUTIONS

- COLD WEATHER ADMIXTURE SYSTEM

- CONSTRUCTION PRACTICES FOR COLD WEATHER CONCRETING

- EFFECT OF COLD WEATHER ADMIXTURE SYSTEM ON CONCRETE [FRESH]

- EFFECT OF COLD WEATHER ADMIXTURE SYSTEM ON CONCRETE [HARDENED]

- USING NANO-MATERIALS IN COLD WEATHER CONCRETE

In this article, we will speak of the curing methods of concrete in cold weather.

Curing Methods of Concrete in Cold Weather

According to codes and specifications, if concrete is to be cast in temperatures below 5°C, special precautions have to be taken to protect concrete from the damages caused by casting in cold weather.

An example for the damages that can occur for concrete cast and cured in slightly low temperature [10°C] is the loss of approximately 30% of concrete compressive strength.

But if concrete was well protected, even if cured at low temperature, it can actually can higher than expected strength at 28 days, compared to normal cured concrete. The extra strength gain can reach 10% for 5°C and 15% for 10°C

So, if this damage can happen for concrete when the curing temperature reaches just 5°C, imagine what can happen if temperature drops below zero!!

That is why the topic of curing methods of concrete in cold weather has attracted much attention in recent years for researchers and practitioners trying to develop specific techniques and methods to protect and cure concrete placed in cold weather.

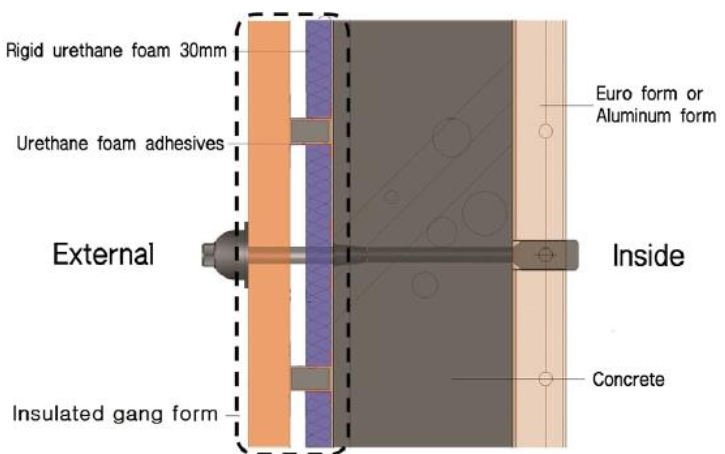

For example, in 2016, a scientist called Wang fabricated in collaboration with his team an insulated gang form through integrating a rigid urethane board into ordinary gang form. They cast concrete and cured it in a chamber with a temperature varying between -5 oC to -15 oC. This gang form showed efficient retention of concrete temperature which in turn improved the development of initial concrete strength.

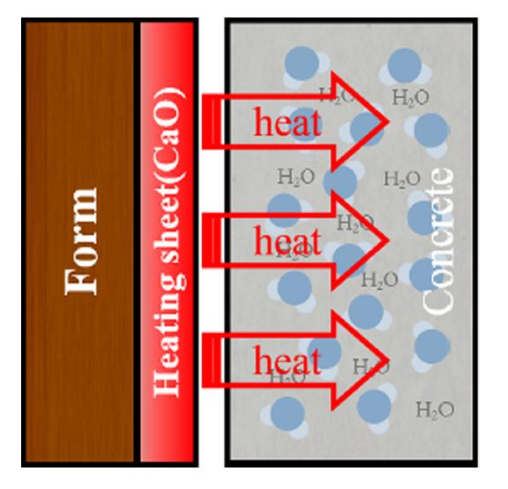

Another example for the breakthroughs regarding the curing methods of concrete in cold weather is the heating sheet developed by Choi in 2017. This sheet exploited the exothermic reaction between quicklime and water, which was used to provide concrete with heat to accelerate the hydration process when the air temperature was -10 ℃.

Choi found that the compressive strength of mortar after 3 days of casting was around 3.5 MPa which in fact, the value required by ACI 306R to protect concrete and prevent frost damage. Comparing to the mortar cured without the sheets, the strength of protected concrete was 3 times higher.

Concrete may harden more quickly during the winter months by using electric heating technologies such contact heating, electrode heating, and induction heating.

The electric contact heating method relies on radiating or conducting heat from a heater to the concrete’s surface. While the electrode-heating technique warms the concrete like any resistor when electric current flows through it because it relies on the concrete’s resistance after being placed in an electric circuit. The electromagnetic field that is created around a conductor by an electric current flowing through it is the foundation of the induction heating technique. Through heated steel reinforcement, heated steel formwork, or embedded steel, this electromagnetic field will cause Eddy currents, which will heat the concrete.

For instance, McIntosh examined the impact of applying alternating electric current—provided by constant voltage—to freshly poured concrete that had been put at refrigeration on its compressive strength. It was determined that using this electrical approach, concrete placed in such an atmosphere could achieve a compressive strength of 20 MPa after 24 hours.

Examples for heating concrete in cold weather