Ductility is simply a way to measure of the ability of a material (any type of material) to resist deformation when subjected to load. With that said, this is very important in civil engineering in general and in structural engineering in particular.

We want our buildings to have some sort of ductility. Imagine having a ruler. If it is made of flexible plastic and you bend it, it will bend and develop some stretch marks before it breaks. What if it was made of rigid plastic? It will just breaks when we bend it beyond its ability to resist deformation.

That’s why we need a minimum level of ductility in our structures. Otherwise, failure will be sudden without any warning, which is actually a not favorable thing because we need those warnings to have enough time for repair works or evacuation in extreme situations.

In this article, we will discuss a little bit the concrete ductility.

We all know that concrete is a brittle material. By it self, it has a minimal level of ductility. Concrete breaks without any warning. Look at the below image.

Therefore, we introduce the reinforcing steel bars in concrete to help increase it overall level of ductility and resist the developed tensile stresses.

Therefore, when we mention the term “concrete ductility”, we usually refer to “concrete reinforced with something”. This could be (concrete + steel bars), (concrete + fiber bars), (concrete + fibers), etc.

Ductility will mean the same thing for all cases.

Concrete Ductility

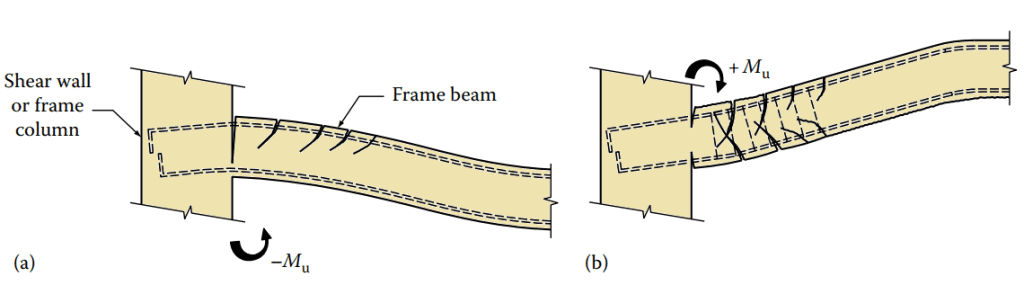

To discuss the “ductility” of reinforced concrete elements, let us look at the typical example of frame-beam.

This frame-beam system is a widely used type in reinforced concrete buildings, especially those designed to resist lateral loads such as wind loads and earthquake loads.

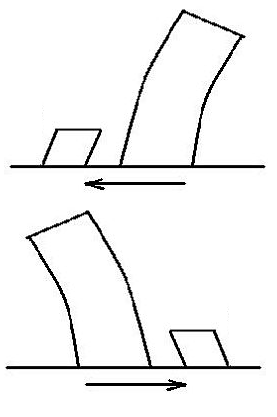

What distinguishes frame-beam from the normal beam (we call it “gravity beam”) is that due to the nature of lateral load (such as seismic ground motions), the loads are reversible.

For example, in case of an earthquake, you will find the building moves in multiple directions back and forth. Not just pushing or pulling. a back and forth motion.

Look at this figure back again

If the load is reversible this will mean that when subjected to seismic ground motions, the frame sways back and forth resulting in flexural and shear cracks in the beam. These cracks close and open alternately due to load reversal and following several cycles of loading, the beam will resemble the previous image. As a result of the back and forth lateral deflections, the two ends of the beam are divided into a series of blocks of concrete held together by the reinforced cage.

If the beam cracks, shear is carried across the crack by the longitudinal reinforcement acting like a dowel and by shear friction along the crack.

The longitudinal bar will buckle if not held in place by stirrups that are spaced closely after the concrete outside the reinforcement crushes.

Ductility is the general term that describes the ability of the structure or its components to provide resistance in the inelastic domain of response.

It contains qualities that are essential to a building’s survival during and after a strong earthquake, such as the capability to withstand significant deformations and the ability to absorb energy through hysteretic activity.

The single most essential quality sought by the designer of structures located in areas of strong seismicity is the capacity to preserve a high proportion of their strength, which guarantees survival of buildings when a big earthquake imposes large deformation.

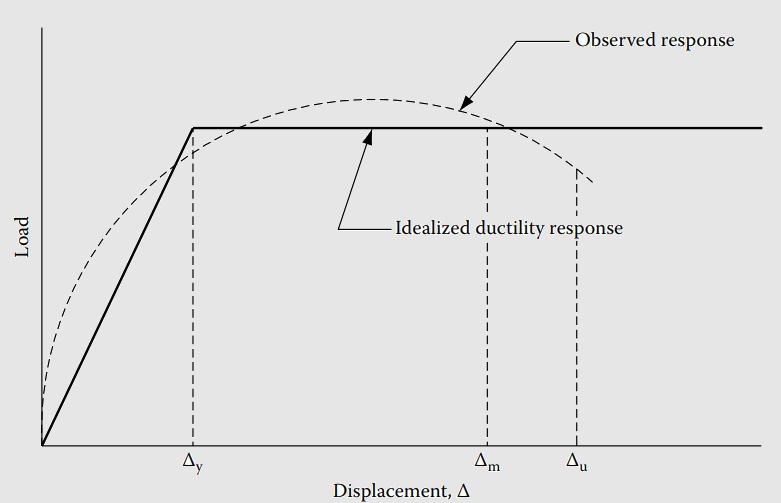

The limit to ductility, such as the displacement of Δu, typically corresponds to a specified limit to strength degradation.

Significant more inelastic deformations may still be feasible without structural collapse even after reaching this limit (we call this limit “failure”)

On the other side, brittle failure denotes a nearly total loss of resistance, frequently leading to full disintegration without sufficient forewarning. For these reasons, brittle failure, which accounts for the vast majority of building collapses during earthquakes and the ensuing fatalities, must be avoided.

Measuring Ductility

Ductility is defined by the ratio of the total imposed displacements Δ at any instant to that at the onset of yield Δy.

From the below figure, we have

degradation.

In terms of strain, curvature, rotation, or deflection, ductility can also be described.

An important consideration in the determination of the required seismic resistance will be that the estimated maximum ductility demand during shaking, μm = Δm/Δy does not exceed the ductility potential μu.

Only ductile component materials allow for the development of ductility in structural members. Concrete is a substance that is brittle by nature. Its compression strengths may be carried with ease, despite the fact that its tensile strength cannot be depended upon as a major source of resistance. However, unless extra care is taken, the maximum stresses that can be created during compression are somewhat constrained to 0.003. In order to generate ductile components that can withstand the inelastic deformation demands imposed by powerful earthquakes, mild steel reinforcement and concrete are combined as the main goal of seismic detailing of concrete structures.

Read Also: