Blast Furnace Slag

This article is for the discussion of blast furnace slag; how it is made, what are the types, and a lot more information.But let us start the story from the beginning by defining what is concrete?

What is Concrete?

Concrete is the most commonly used construction materials in the world. The availability of concrete as an abundant, local and cost-effective building material makes it perfect as a construction material. In additions to this, concrete is a durable, flexible and resilient material.

Concrete is simply defined as:

a blend of aggregates, normally natural sand and gravel or crushed rock. These are bound together by a hydraulic binder e.g. Portland Cement and activated by water to form a dense semi homogenous mass.

We call the portland Cement activated by water as cement paste.

Therefore, the composition of concrete is basically cement paste + aggregates. We can write this in an equation form:

concrete = cement paste + aggregates

We know that cement paste is made from cement and water. Also, the aggregates are divided into coarse (such as gravel and crushed stone) and fine (such as sand) aggregates.

Thus, concrete = cement + water + fine aggregate + coarse aggregate

In some cases, we need to add admixtures to the previous components to give additional features to concrete such as higher strength, higher workability and so on. Therefore, the equation turns to:

concrete = cement + water + fine aggregate + coarse aggregate + admixtures

All is well so far. so what is Blast Furnace Slag? what makes us want to use it in our concrete? To answer this question, let me first tell you the problem with normal cement so that you can appreciate the benefits of addition of slag.

Environmental Problem of Cement

Although cement has a significant role in concrete and we can not basically make concrete without cement (actually there is a type of concrete without cement but this is a special type of concrete), there is one huge environment concern.

The cement industry is responsible for about 8% of global carbon dioxide emissions, more than double those from flying or shipping. If it were a country its yearly pollution would only be topped by the US and China.

Nevertheless, every year, more than 4 billion tonnes of cement are produced for use in the construction of buildings, roads, flood barriers, and other things. As more people from developing countries move to cities and want housing and infrastructure comparable to those in more affluent parts of the world, its usage is expected to rise. More cement was poured globally between 2011 and 2013 in only a few short years than the United States did throughout the entire 20th century. China manufactures more than half of all cement globally.

The fundamental issue is that [concrete] is very carbon intensive, which is a serious concern, yet we probably aren’t doing enough to address it, according to Johanna Lehne, a decarbonizing industrial processes expert at the climate think tank E3G in Brussels.

A Potential Solution?

Research was then directed to find other materials that can be implemented in concrete as cement replacement to help reduce the amount of cement, while at the same time, does not compromise the properties of concrete.

One of these materials is the “blast furnace slag”

So, what happens is you reduce the amount of cement; instead of using 100% cement, now we can use less amounts. The equation for example turns to:

concrete = % of normal cement + % of blast furnace slag + water + fine aggregate + coarse aggregate + admixtures

What is blast furnace slag ?

Blast furnace slag (also called fine granulated blast furnace slag [GGBFS]) is a material that we call as one of the supplementary cementitious materials.

Ground granulated blast furnace slag is the glassy material formed from molten slag produced in blast furnaces as an industrial by-product from the production of iron used in steelmaking.

Next, let us talk about the manufacture process of slag and what percentage to be added to the portland cement and a lot more.

Production of blast furnace slag cement

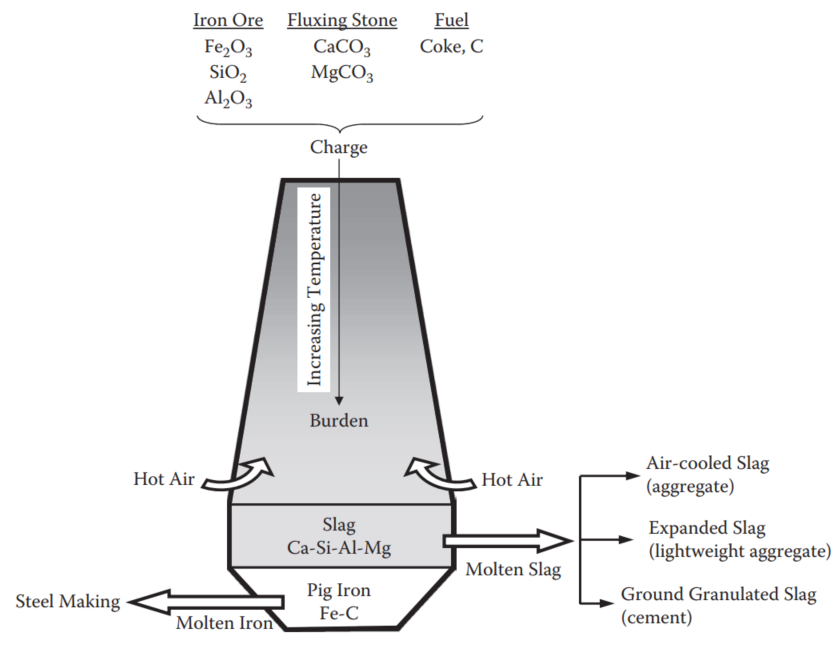

The following image shows a schematic diagram for an iron blast furnace.

The raw materials that are added into the furnace from top are:

- Iron ore,

- A fluxing stone (usually a combination of limestone and dolomite),

- Coke as fuel

These materials are continuously added from the top and hot air is blasted in farther down.

The raw materials ignite, and their temperature reach more than 2000°C.

At this temperature, the iron oxide in the ore is converted to molten iron (also called pig iron), which, because of its high density, falls to the bottom of the furnace.

The slag is formed from the remaining ingredients, which consist of the calcium and magnesium from the fluxing stone, the alumina and silica gangues from the iron ore, and a small amount of ash from the coke.

These ingredients form a fused melt that floats above the denser molten iron.

Both the iron and slag are tapped or drawn off from the furnace at regular intervals, and it is a continuous (rather than batch) process.

Pig iron is used to create steel, and the by-product slag has a variety of uses as well. It is possible to pour the material into trenches, let it air cool, and then crush it to make a normal-density aggregate.

Alternatively, expanded slag lightweight aggregate can be produced by mixing the molten slag with water.

The slag can be processed in a way that makes it acceptable for use as a cementitious component in concrete.

To transform the molten slag into a cementing material, it must be rapidly cooled (granulated), dried, and then ground to a fine powder. The resulting product is known as ground granulated (iron) blast furnace slag. We simply call it slag.

Note that ground granulated (iron) blast furnace slag is not the same as the steel slag produced during the steelmaking process, which takes place after the creation of pig iron in an iron blast furnace, and that it is typically inappropriate for use as a cementing agent in concrete.

To create cementitious slag, the molten blast furnace slag is rapidly cooled (quenched) from a temperature of around 1500°C by quenching with water to form a glassy structure.

Granulation is the name of the procedure, which entails carefully dumping the slag into a stream of water. The finished product resembles coarse sand grains.

The slag will form the glass structure only if it is rapidly cooled. It is this glass that displays hydraulic or cementitious properties. If the slag is allowed to cool slowly in air, it will form crystalline products and will have no cementitious value.

The granulated slag is then dried before being ground in a ball mill, or similar equipment, to produce a fine powder material of approximately the same or greater fineness than portland cement.

Classification of blast furnace slag

According to the American Concrete Institute (ACI), slag is classified based on its slag activity index (SAI).

SAI is determined based on the strength of mortars as:

SAI = SP / P * 100%

where SP and P are, respectively, the compressive strengths of mortar cubes containing 50% and 0% (control) slag.

According to the 7-day and 28-day strength activity indices, ASTM C989 offers three categories of slag, as illustrated in the following table:

What, specifically, makes blast furnace slag suitable for use as a cement replacement? its composition is the answer.

Composition of blast furnace slag

| Oxide | Range (%) |

| SiO2 | 32-42 |

| Al2O3 | 7-16 |

| CaO | 32-45 |

| MgO | 5-15 |

| S | 0.7-2.2 |

| Fe2O3 | 0.1-1.5 |

| MnO | 0.2-1.0 |

Properties of Blast Furnace Slag

The reactivity of slag is influenced by its chemical components. In general, the reactivity rises with alkalinity, calcium, alumina, and magnesium concentration—at least up to 10% MgO—while falling with silica and magnesium content.

As the slag’s alumina concentration rises, the early strength of mortars and concretes tends to rise as well, and this is thought to be due to more ettringite forming at early age.

As the fineness of the slag increases, so does its reactivity. Typically, slag is crushed to a fineness between 400 and 650 m2/kg, producing angular-shaped particles with a particle size distribution resembling portland cement.

The specific gravity is typically 2.9, and the bulk density is close to 1200 kg/m3.

The finished product resembles white cement.

Proportion of blast furnace slag

So, now we need to know what is the amount we should add to our concrete as a replacement to cement?

The kind of application has a big impact on how much slag you put to Portland cement. The following table shows the required proportions for each application:

| Application Type | blast furnace Slag % |

| General type of construction such as buildings and roads | 25 to 40 |

| Less heat of hydration such as in case of mass concrete | 30 to 50 |

| Concrete elements subjected to chloride attack | 25 to 50 |

| Concrete elements subjected to sulfate attack | 30 to 50 |

Note: the previous proportions are for guidance only. You should do trial batches to make sure you are getting the properties that you want.

Applications of Blast Furnace Slag

There are numerous applications and uses for slag such as:

- Enables the creation of stronger concrete

- Produces concrete with a lower permeability, making it suited for piles and marine constructions that are susceptible to chloride and sulphate attacks.

- Because it produces concrete with a lower hydration temperature, it is a viable option for large-scale structures (mass concrete) like dams.

- Excellent option for retaining walls, tunnels, and other constructions that need to retain water or earth.

- Slag is preferred by concrete manufacturers because it is less expensive than ordinary cement.

Benefits and Advantages of Blast Furnace Slag

- The initial strength achieved is less than the conventional concrete, but the superior ultimate strength attained is equivalent and sometimes higher than conventional concrete.

- Because the slag is finely powdered, it has the potential to effectively fill the pores, has a high degree of workability, and exhibits less bleeding.

- It is resilient to attacks from sulphate and chloride, and there is even less chance of an alkali-silica reaction with aggregates.

- The slump retention and initial setting time are longer as a result of the intentional hydration procedure.

- Due to fineness, there is more strength and less penetrability.

- Due to the white color of GGBFS, the cement color obtained is brighter colored when compared to conventional cement.

- The production cost of this cement is less than the Ordinary Portland Cement (OPC).

Limitation and Disadvantages of Blast Furnace Slag

- Some types of slag has a slow rate of early strength gain, which makes these types unsuitable for saturations where high early strength is required such as repair works.

Read Also: