Accelerated Curing of Concrete for Rapid Strength Testing

Accelerated Curing of Concrete: Typically, when we work with concrete, we require a specific strength at 28 days of age. So, what happens is we cast specimens or we take specimens from the concrete batch and then we cure it for 28 days and test for the value of the compressive strength.

In some cases, we require to have the value of the strength at an earlier age because we can not wait for the full 28 days. Here, ASTM C684 (there are other specs for other countries) provides you with some methods that accelerates the curing process of concrete specimens (Accelerated Curing of Concrete) so you can test your specimens earlier.

Benefits of Accelerated Curing of Concrete

Other than the earlier testing of concrete, there are other advantages for the accelerated curing methods of concrete such as the following:

- Precast concrete plants can use these curing methods because they need to obtain high strength at early ages so they can remove the formworks faster and of course, this will increase the production amounts and cut the waiting costs.

- In cold regions, concrete has to harden quickly otherwise it might get damaged so rapid curing methods are essential in these areas.

Methods of Accelerated Curing of Concrete ASTM C684

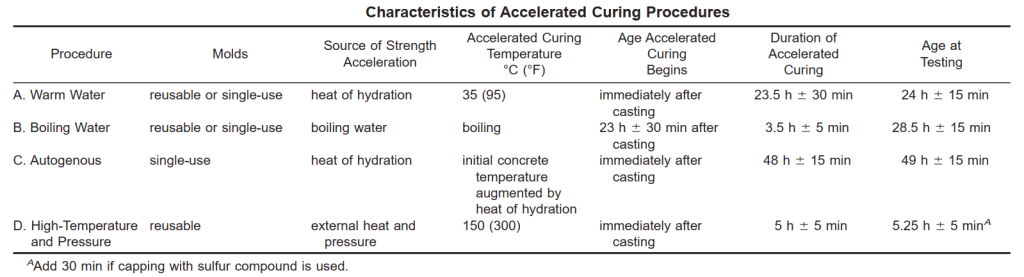

There are four methods for Accelerated Curing of Concrete specimens:

- Warm Water Method

- Boiling Water Method

- Autogenous Curing Method

- High Temperature and Pressure Method

Summary of ASTM C684

- Prepared concrete specimens are subjected to accelerated curing methods/conditions that make the concrete develop a significant amount of their ultimate strength within a time range from 5 to 49 h (depending on which curing method is used).

- Method A and B (Warm Water Method and Boiling Water Method) stores the specimens in heated water at elevated curing temperatures without moisture loss. In method A, the warm water (moderately heated) acts as an insulation that keeps the generated heat of hydration and prevents its loss. In Method B, the higher temperature provides additional thermal acceleration.

- Method C [Autogenous Curing Method] involves storage of specimens in insulated curing containers in which the elevated curing temperature is obtained from heat of hydration of the cement. The sealed containers also prevent moisture loss.

- Method D [High Temperature and Pressure Method] involves simultaneous application of elevated temperature and pressure to the concrete using special containers.

Accelerated Curing of Concrete

- Sampling and testing procedures are the same as for normally cured specimens (see Practice C 172 and Test Method C 39, respectively)

IMPORTANT: The accelerated early strength obtained using any accelerated method can be used to evaluate concrete strengths in the same way conventional 28-day strengths have been used in the past, with suitable changes in the expected strength values. Since the practice of using strength values obtained from standard-cured cylinders at 28 days is long

established and widespread, the results of accelerated strength tests are often used to estimate the later-age strength under standard curing. Such estimates should be limited to concretes using the same materials and mixture proportions as those used for establishing the correlation.

Equipment and Tools

- You need the small tools to prepare the specimens such as the scoops, rod, etc.

- If needed, slump test tools and air meter.

- Cylindrical molds.

- Accelerated Curing Tank with a lid for Methods A and B. The tank is of any configuration suitable for the number of cylinders to be tested. Arrange the cylinders in any configuration that provides a clearance of at least 50 mm between the side of each cylinder and the side of the tank, and at least 100 mm between adjacent cylinders. Maintain the water level at least 100 mm above the tops of the cylinders.

- The tank should be able to provide the specified water temperature, maintain the water temperature within 63°C of the specified value at any point in the water, and limit the temperature drop, after immersion of specimens.

- Thermometers to check the temperature of the water.

- Curing Container for Method C should have thermal insulation meeting heat retention requirements and closely surrounding the concrete specimen.

- Curing Apparatus for Method D consists of a loading system to apply the specified pressure to the concrete specimens and special molds to maintain the concrete specimens at the specified temperature during the curing period.

Compressive Strength Testing Methods using Accelerated Curing Procedures

Method A: Warm Water Method

- Prepare the concrete specimens; mould the specimens according to ASTM C31 or ASTM C192.

- Before starting the curing, you may need to cover the top of the specimens with a rigid lid to prevent the mortar loss to the water.

- Right after molding the specimens, put them in the curing tank with water kept at a temperature of 35±3°C during the curing duration.

- Record the temperature of curing water either continuously or periodically throughout the curing period.

- After curing for 23.5 hours ± 30 min, remove the specimens from the tank and remove the molds.

- Prepare the specimens for testing by either capping or grinding.

- Test the specimens for strength according to ASTM C39 at the age of 24 h ± 15 min.

Method B: Boiling Water Method

- Prepare the concrete specimens; mould the specimens according to ASTM C31 or ASTM C192.

- Initial cure the specimens by covering them to prevent loss of moisture and store at a temperature of at 21 ± 6°C.

- After 23 hours ± 15 min of casting, place the covered molds in the water tank. Maintain the temperature of the water at the time of immersion and throughout the curing period at boiling.

- Record the temperature of curing water either continuously or periodically throughout the curing period.

- After curing for 3.5 hours ± 5 min, remove the specimens from the tank and remove the molds.

- Allow the specimens to cool at room temperature for at least 1 hour prior to capping.

- Prepare the specimens for testing by either capping or grinding.

- Test the specimens for strength according to ASTM C39 at the age of 28.5 h ± 15 min.

Method C: Autogenous Method

- Prepare the concrete specimens; mould the specimens according to ASTM C31 or ASTM C192.

- Right after casting the specimens into the molds, cover the mold with a tight lid.

- Reset the thermometer and put the specimens in the container and close the container with the lid.

- Record on the outside of the container, the time of molding and the temperature of the freshly molded concrete.

- Store the curing container for at least 12 h in a location not subject to disturbance or direct sunlight, and preferably at a temperature of 21 ± 6°C.

- Remove the specimens for the container at the age of 48 hours ± 15 min after casting.

- Leave the specimens in at room temperature for 30 minutes.

- Record the the maximum and minimum temperature from the thermometer and write it on the container.

- Prepare the specimens for testing by either capping or grinding.

- Test the specimens for strength according to ASTM C39 at the age of 49 hours ± 15 min.

Method D: High Temperature and Pressure Method

- Use steel molds in this case.

- Method D is limited to concrete containing aggregate with a maximum size of 25 mm

- Prepare the concrete specimens; mould the specimens according to ASTM C31 or ASTM C192.

- Fill the concrete in mold in two layers.

- Right after casting the specimens into the molds, cover the mold with a tight lid.

- Stack the molds vertically and place them in the loading apparatus.

- Apply and maintain a pressure of 10.3 ± 0.2 MPa on the concrete in the molds.

- Raise the temperature of the specimen to 150 ± 3°C within 30 ± 5 minutes. The curing period starts once the temperature increases.

- Cure specimens for 5 h ± 5 min. During the first 3 h, maintain the specimen temperature at 150 ± 3°C. After 3 h, turn off the heat and maintain the pressure at 10.3 ± 0.2 MPa for the remainder of the curing period.

- At the end of the curing period, release the pressure, remove the molds from the loading apparatus, and remove the specimens from the molds.

- Test the specimens for strength according to ASTM C39 within 15 minutes after removing the molds and after 30 minutes after capping if you will need capping.

Read more on the test in: Standard Test Method for Making, Accelerated Curing, and Testing Concrete Compression Test Specimens

Read Also: Compressive Strength Test of Concrete