Air Content of Freshly Mixed Concrete by the Volumetric Method

Purpose of ASTM C173

This method is used for the purpose of determination of the air content of fresh concrete composed of any type of fine/coarse aggregate. The volumetric method requires the removal of air from a known volume of concrete by agitating the concrete in an excess of water. The procedure described in this manual is applicable for concrete mixtures with a maximum size aggregate passing the 37.5-mm sieve. An advantage of the test is that it is not affected by atmospheric pressure and the relative density (specific gravity) of the materials need not be known.

Why is the Air Content in Concrete Important?

Concrete exposed to freezing and thawing cycles like in cold regions or fridges that serve in low temperatures can be severely damaged if not well protected.

One of the main methods to protect concrete exposed to freezing and thawing cycles is to introduce air content in concrete at certain percentages as demonstrated by various codes.

In this case, the introduced air bubbles serve as locations for pressure relief in concrete that protects it from damage.

That is why it is important to introduce air bubbles in concrete and test the concrete to make sure that the correct value required is obtained. This is the purpose of ASTM C173

Principle of ASTM C173 Air Content of Freshly Mixed Concrete

Testing for volumetric air content begins with the consolidation of a concrete specimen with a known volume into a container. Water, isopropyl alcohol, or both can be filled to the zero point in a cover with integral graduated markings that is sealed on top. The specimen is then violently agitated, effectively washing away the air spaces throughout the whole assembly. The air content is calculated as the difference between the fluid’s pre- and post-agitation levels.

Roller metres typically have a 2.0L or larger measuring bowl and are made of aluminium, plastic, or brass. A clear graduated scale and a clamp-on top portion are included. The bowl is filled with concrete and the top portion is fastened in place. The assembly is subsequently filled with mixtures of water and isopropyl alcohol in calculated proportions. After agitation, certain concrete mixtures develop a significant quantity of foam, which the alcohol disperses to enable more precise fluid level readings.

Needed Equipment

Tools for ASTM C173 (Air Content of Freshly Mixed Concrete)

The following apparatus are used to conduct the ASTM C173 test:

- Air meter that is made of a bowl and top. The bowl shall have a volume of at least 2.1 liters and have a diameter 1 to 1.25 times the height and constructed with a flange at or near the top surface. The top section shall have a capacity at least 20% greater than the bowl and have a watertight connection to prevent seepage; it shall also be equipped with a transparent scale, graduated in increments not greater than 0.5% from 0 to ≥ 9% of the volume of the bowl.

- Funnel with a spout that can extend to the bottom of the top section.

- Steel tamping rod 16 mm in diameter.

- Flat strike-off steel plate at least 3 mm × 20 mm × 300 mm.

- Metal or plastic calibrated cup having a capacity at least equal to the volume of the bowl and graduated in approximately 1% increments.

- Small rubber bulb syringe having a capacity greater than or equal to that of the calibrated cup.

- Pouring container of about 1 liter capacity.

- Small metal scoop.

- 1 liter of rubbing alcohol.

- Rubber mallet about 0.60 kg.

PPE (Air Content of Freshly Mixed Concrete)

- Safety glasses

- Rubber gloves

- Mask

- Steel-toed shoes

ASTM C173 Test Procedure

Step 1:

Calibrate the air meter and the calibrated cup initially and annually or whenever the volume of either is suspect.

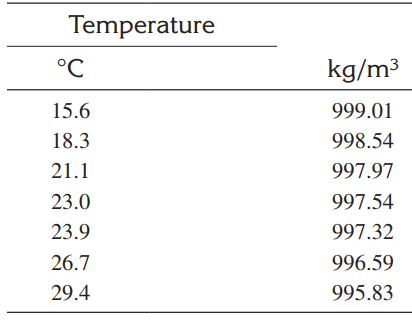

The volume of the measuring bowl is determined by carefully weighing the amount of water and its temperature to fill the measuring bowl.

Using the information below and any required interpolation, determine the mass of water in the bowl. The volume, V, is then determined by dividing the mass of water needed to fill the measuring bowl by the table’s indicated density.

Using the same procedure, calculate the graduated measuring cup’s volume.

Determine the accuracy of the graduations on the neck of the top of the air meter by filling the assembled bowl and top section with water to the level mark for the highest air content graduation.

After that, fill the bowl with water in 1.0 percent-amount increments along the graded range of air. At no time can the inaccuracy be greater than 0.1 percent of air.

Step 2:

Three layers of concrete should be added to the measuring bowl, and each should be tamped 25 times with the rod. To get rid of any voids or air bubbles that may have become trapped, hit the edges of the bowl 15 times with the rubber mallet after each lift has been rodded.

Step 3:

Strike off the excess concrete from the top of the bowl and wipe the flange clean. Then attach the top section to the bowl and insert the funnel. With the rubber syringe and using a mixture of 50% water and 50% alcohol, pour enough liquid into the air meter assembly to raise the bottom of the meniscus to the zero mark. Attach and tighten the watertight cap.

Step 4:

For at least 45 seconds, flip the assembly over and shake it up. To avoid the concrete mass being stuck in the neck, don’t leave the unit inverted for longer than five seconds at a time.

Step 5:

Tilt the assembly at about a 45° angle and roll it back and forth vigorously for approximately 1 minute. Then take a reading.

Step 6:

Repeat the preceding method a second time, then take a reading one minute later. Repeat this process until there is no more than a 0.25 percent air difference between two measurements. Always read the meniscus all the way through.

Step 7:

Use the syringe to add alcohol in precisely measured one-cup increments to create a legible meniscus if the liquid level is hidden by foam. Keep track of how many calibrated cups of alcohol were consumed.

Step 8:

Disassemble the apparatus and examine the contents. If any portion of the concrete mass has not been disturbed during the procedure, the test is considered invalid and must be repeated.

Computations

Computations

The air content, as a percent of the concrete in the measuring bowl, is obtained from Test Procedure Step 6, to the nearest 0.25%. If it was necessary to utilize additional alcohol to clear the foam, as described in Test Procedure Step 7, the quantity of additional alcohol must be added to the observed percent of air.

Relation between Air Content and Freeze Thaw Resistance of Concrete

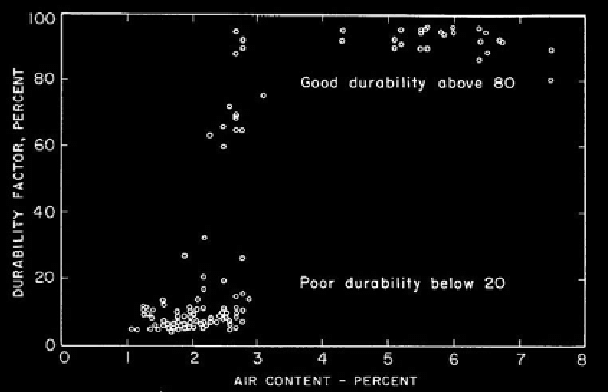

As you can see in the below figure, the higher air content results in higher resistance of concrete to freezing and thawing

Reference: Standard Test Method for Air Content of Freshly Mixed Concrete by the Volumetric Method

Read Also:

ASTM C128 Obtain Specific Gravity and Absorption of Fine Aggregate