Los Angeles LA Abrasion Test of Coarse Aggregate

Purpose of ASTM C131

This post describes the procedure of ASTM C131 to determine the resistance of coarse aggregate smaller than 37.5 mm in size to abrasion, using the Los Angeles Testing Machine.

Why is the Resistance to Abrasion Important?

We do the LA abrasion test on coarse aggregate to give an indication on its quality and specifically, the hardness and toughness of aggregate.

As you know, aggregate may be used in case where concrete will suffer from wearing due to external movements such as cars causing abrasion on roads or water causing errosion in canals.

That is why in such cases, we need to use a type of aggregate that has the ability to resist such weathering conditions, otherwise, significant wear will occur.

Principle of L.A. Abrasion Test

The principle of Los Angeles abrasion test is to determine the percentage wear due to relative rubbing action between the aggregate and steel balls used as abrasive charge. So, this means that we induce abrasive action on the aggregate and see how much material the aggregate lose. Typically, we use steel balls (sometimes called steel spheres) as the abrasive tool.

As the drum of the L.A. abrasion machine rotates, there is a shelf plate that picks up the aggregate sample and the steel balls, carrying them around until they drops to the opposite site of the drum. This process creates an impact and crushing effect.

The contents roll in the drum under an abrading and grinding action until the shelf plates picks the aggregate sample and balls and repeat the cycle again.

The drum rotates for a preset number of rotations (revolutions) and then contents are taken from the drum. We sieve the aggregate sample to evaluate the percent loss of the particles.

Needed Equipment and Materials

Tools for ASTM C131 (LA Abrasion Test of Coarse Aggregate)

The following apparatus are used to conduct the ASTM C131 test:

- A scale.

- Los Angeles testing machine (L.A. Abrasion machine).

- Abrasive charge as per the following table. The abrasive charge consists of steel spheres approximately 47.6 mm in diameter, each ball weighing between 390 and 445 grams.

| Grading | Number of Spheres | Mass of Charge (grams) |

| A | 12 | 5000 ± 25 |

| B | 11 | 4580 ± 25 |

| C | 8 | 3330 ± 20 |

| D | 6 | S2500 ± 15 |

- Sieves according to the specs of ASTM E11

- An oven with enough space and capable of maintaining a uniform temperature of 110 plus or minus 5 °C

PPE (LA Abrasion Test of Coarse Aggregate)

- Safety glasses

- Rubber gloves

- Mask

- Steel-toed shoes

Materials

A sample of coarse aggregate according to the following table:

| Sieve Size | Weight of Indicated Size in Grams Aggregate Grading |

||||

| Passing sieve size (mm) | Retained on sieve (mm) | A | B | C | D |

| 37.5 | 25 | 1250 ± 25 | |||

| 25 | 19 | 1250 ± 25 | |||

| 19 | 12.5 | 1250 ± 25 | 2500 ± 10 | ||

| 12.5 | 9.5 | 1250 ± 25 | 2500 ± 10 | ||

| 9.5 | 6.3 | 2500 ± 10 | |||

| 6.3 | 4.75 | 2500 ± 10 | |||

| 4.75 | 2.36 | 5000 ± 10 | |||

| Total | 5000 ± 10 | 5000 ± 10 | 5000 ± 10 | 5000 ± 10 | |

ASTM C131 Test Procedure

- First, you need to obtain the sample of coarse aggregate from the field and reduce it to an adequate size according to ASTM C702.

- If the reduced aggregate sample is clean from dust, debris or any coating material, you can use it directly to the next step. If not, wash the sample for cleaning.

- Put the sample in oven for drying until constant weight. The temperature of the oven should be 100° to 110°C.

- Separate the sample into individual size fractions, and recombine these fractions to the grading of the previous table.

- Record the mass of the sample before testing to the nearest 1 g.

- Place the test sample and the abrasive charge in the Los Angeles Abrasion Machine. The machine should rotate at a speed of 30 to 33 rpm for 500 revolutions.

- After rotating for the number of cycles, remove the aggregate sample and debris from the machine.

- Make initial seperation of the material on sieze 1.7 mm (#12).

- The finer portion is to be sieved on sieve 1.7 mm (#12).

- The material retained on sieve 1.7 mm in the previous step is oven dried until constant mass. The temperature of the oven should be 100° to 110°C.

- Take the sample out of oven and measure the weigth to the nearest 1 gram.

Computations

Computations (LA Abrasion Test of Coarse Aggregate)

Calculate the difference between the original sample weight and that retained on the 1.7 mm (# 12) sieve. Express that value as a percentage of the original sample weight. This value is considered as the percentage of wear (also called the percent loss).

Percentage of wear = (W1 – W2) / W1 * 100 = …… %

Where:

W1 = mass of original test sample (grams)

W2 = final mass of the test sample (grams)

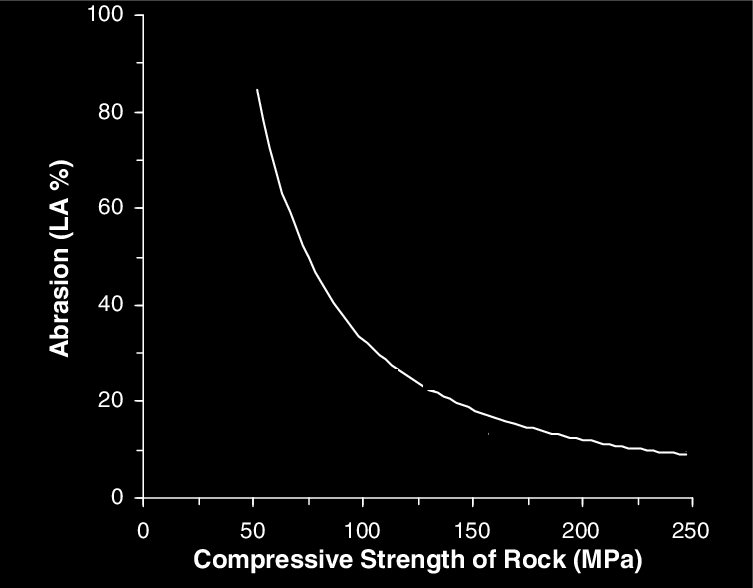

Relation between Abrasion loss % and Strength of Rock

As you may expect, there is an inversely proportional relatioship between the aggregate compressive strength and the percentage of wear. This means that the higher the strength, the less abraded materials found.

Reference: Standard Test Method for Resistance to Degradation of Small-Size Coarse Aggregate by Abrasion and Impact in the Los Angeles Machine

Read Also:

ASTM C127 Obtain Specific Gravity and Absorption of Coarse Aggregate