Specific Gravity and Absorption of Fine Aggregate

In this article, we discuss the methodology and test procedure described in ASTM C128 to conduct the experiment related to the specific gravity and absorption of fine aggregate.

Purpose of ASTM C128

The aim of “Standard Test Method for Relative Density (Specific Gravity) and Absorption of Fine Aggregate” is to determine the bulk and apparent specific gravities of fine aggregate, which provide an indication of the quality of aggregates.

Distinction is made between the bulk density of aggregates, which takes into account the volume of voids between aggregate particles, and the density of aggregate particles, as measured by Test Method C29/C29M.

In addition, the purpose of ASTM C128 is to find the absorption of fine aggregate, where absorption is the process by which water is drawn into and tends to fill the permeable pores in a porous solid body.

What is relative density or specific gravity?

Relative density, also known as specific gravity or the absolute volume of the aggregate, is the ratio of the mass of an aggregate to the mass of a volume of water equal to the volume of the aggregate particles. The ratio of the aggregate particle density to the water density is another way to state it.

Needed Equipment and Materials

Tools for ASTM C128 (Specific Gravity and Absorption of Fine Aggregate)

To determine the specific gravity and absorption of coarse aggregate, the following tools are needed:

- A scale that has a minimum capacity of 2 kgs and accuracy of 0.1 grams.

- 6 pycnometers with a capacity of 500 ml.

- A conical sheet metal brass mold; Diameter = 40 mm at top and = 90 mm at bottom; Height = 75 mm.

- A tamping rod of metal with a circular flat tamping face; diameter of the circle is 25 mm.

- Sieves: 4.75-mm (No. 4) sieve

- An oven with enough space and capable of maintaining a uniform temperature of 110 plus or minus 5 °C

- Small splitter

PPE (Specific Gravity and Absorption of Coarse Aggregate)

- Safety glasses

- Rubber gloves

- Mask

Materials

The sample required from fine aggregate is 3 kg. All sample should pass from sieve No. 4 (4.75 mm).

ASTM C128 Test Procedure

- First, you need to obtain the sample of fine aggregate by either sample splitting or quartering 3 kgs of aggregate. Get equal quantities from all fractions.

- Put the sample in oven for drying until constant weight. The temperature of the oven should be 100° to 110°C.

- After drying, allow the sample to cool at room temperature.

- Cover the sample of fine aggregate with clean water for about 30 minutes at room temperature.

- Remove the sample from water and wipe excess water.

- Spread the sample over a flat surface and expose it to a gentle moving flame until the sample reaches a free-flowing condition or instead, you can leave the sample in air for a little bit.

- Put a portion of the fine aggregate sample in the mold and tamp lightly 25 times and then, lift the mold vertically.

- When you remove the mold, notice the shape of sand. If surface moisture still present, the fine aggregate will maintain its shape in the mold. This is not ok.

- You need to continue drying and do the pervious molding step until the aggregate slumps slightly once you remove the mold. This indicates a saturated surface dry (SSD) condition of the aggregate.

- Immediately, put 500 grams of the sample into the pycnometer. Fill the pycnometer almost to its capacity and remove air bubbles by agitation.

- Add water until the bottom of the meniscus is at the 500-cc line, marked on the outside of pycnometer. Then, measure the total weight of the flask that contains the sample and water.

- Carefully remove the fine aggregate from the flask and dry in the oven to a constant weight of 100° to 110°C.

- Cool the sample afterwards for at least 30 minutes and weigh.

Special Instructions

- Find the specific gravities of three fine aggregate samples. Test the fourth sample if necessary to ensure that the three sets of results differ by no more than 2% from one another. Repeat the entire test if these accuracy requirements are not fulfilled.

- Using the correct specific gravity in the design of a Portland cement concrete mix is important. The particular specific gravity used must be consistent with the moisture condition of the aggregates being batched, whether on an oven dry or a saturated surface dry (SSD) condition. Either specific gravity may be used. In an oven dry condition the aggregates do not possess any absorbed or surface water. In an SSD condition, the water-permeable voids of the aggregates are filled with water, but no additional free water is present.

Computations and Data Sheet

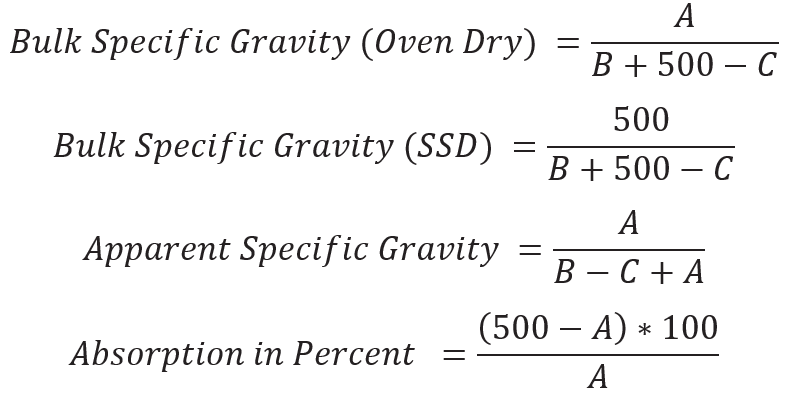

Computations (Specific Gravity and Absorption of Coarse Aggregate)

where:

A = weight of oven-dry sample in air, grams

B = weight of pycnometer filled with water, grams

C = weight of pycnometer with sample and water, grams

Data sheet (Specific Gravity and Absorption of Coarse Aggregate)

You can use the data sheet below to document your findings.

| Passing……sieve & Retained on …… sieve | Sample 1 | Sample 2 | Sample 3 | Sample 4 |

| Oven dry weight of the sample in grams [A] | ||||

| Weight of pycnometer + water to calibration mark in grams [B] | ||||

| Pycnometer + water + sample to calibration mark in grams [C] | ||||

| Bulk specific gravity (bulk SG) | ||||

| Apparent specific gravity (apparent SG) | ||||

| Effective SG | ||||

| Absorption ratio , % | ||||

| Average values for all specimens: Bulk SG = …… Apparent SG = ………. Effective SG = …….. Absorption = ……. % | ||||

Note that you do not have to do four samples as mentioned earlier.

Keep in mind that the last value obtained in the laboratory will be (A), which is the weight of the oven dry sample.

To get the value (A), the aggregates are placed in an oven and dried to a constant weight. The four values, bulk (dry and SSD), apparent, and absorption, are then computed for each sample. Based upon the results, a decision needs to be made as whether or not to test the fourth sample.

The results are finally determined by averaging the values of the samples that meet the requirements for the guidelines. The different mix design computations will then make use of these data. It is crucial to establish precise specific gravities because of this. If the outcomes are in doubt, don’t be hesitant to restart the entire process.

Reference: Standard Test Method for Relative Density (Specific Gravity) and Absorption of Fine Aggregate

Read Also:

ASTM C127 Obtain Specific Gravity and Absorption of Coarse Aggregate