What is ASTM A53?

The term “ASTM A53” refers to a carbon steel alloy that is used as structural steel and also used in low-pressure plumbing. In addition, ASTM A53 refers to a standard developed by the American Society for Testing and Materials that is called “Standard Specification for Pipe, Steel, Black and Hot-Dipped, Zinc-Coated, Welded and Seamless.”

Let us look at the purpose of ASTM A53.

Purpose of ASTM A53 Standard

The aim of ASTM A53 standard specs is to provide details in the properties and characteristics of ASTM A53 steel. It covers seamless and welded black and hot-dipped galvanized steel pipes.

Grades of A53 Steel Covered in ASTM Standard A53

There are three types and two grades of A53 steel:

A53 Type F: longitudinally furnace butt welded or continuous welded (Grade A only)

A53 Type E: longitudinally electric resistance welded (Grades A and B)

A53 Type S: seamless pipe, produced by hot working, and possibly cold finishing, the steel (Grades A and B).

Chemical Composition of A53 Steel

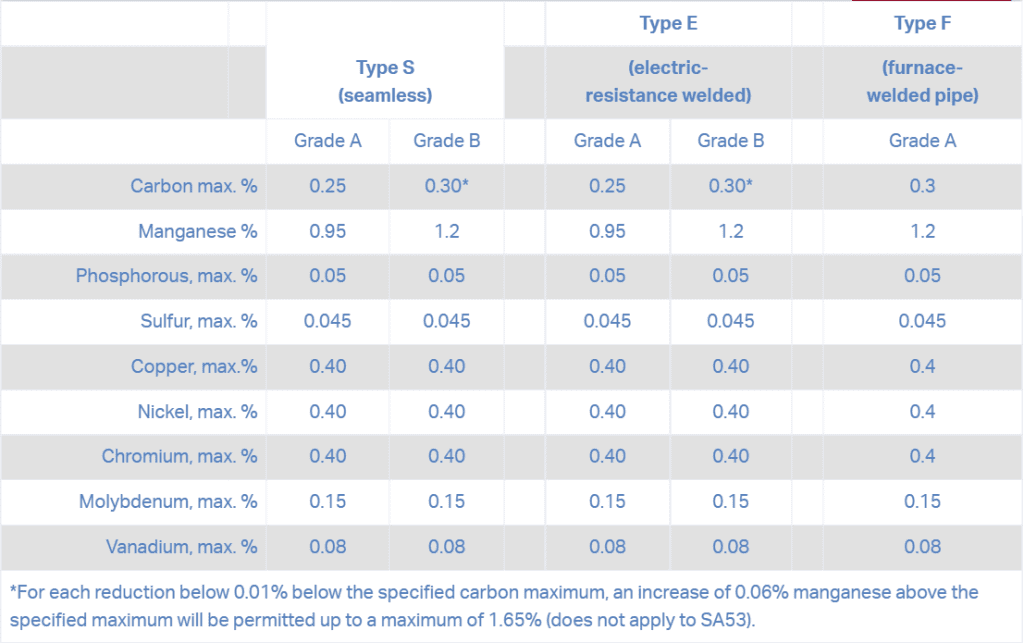

Depending on the type and grade, A53 steel has a different chemical composition. The permitted percentages of carbon and manganese account for the majority of the differences between grades. Grade B can include up to 0.30 percent more manganese than grade A for types S and E. Additionally, they may contain 0.05 percent extra carbon. The B grades in types S and E and type F share a similar composition.

A53 steel is made of multiple chemical elements. It includes the following elements with the specified amounts shown in the table:

Now let us look at the mechanical properties of Steel A53

Mechanical Properties of ASTM A53 Steel

The mechanical properties include:

| Property | Value |

| Modulus of Elasticity (Young Modulus) | 200-215 GPa |

| Poisson’s ratio | 0.29 |

| Shear Modulus | 75-80 MPa |

Advantages and Disadvantage of Steel ASTM A52

The use of A53 steel gives it a relative advantage. Oil, steam, air, or water transportation applications requiring low or medium pressure are best suited for A53. Its chemical makeup is fundamental to its relative disadvantage. Silicon, an alloy that increases heat resistance, is absent from A53. As a result, A53 is not approved for transportation at high temperatures.

Applications of ASTM A53 Steel

Refineries, generating plants, steam conduction, compressor stations, and natural gas transmission facilities all use A53 as an all-purpose pipe. A53 steel pipe is typically used by businesses in the process industries because it functions effectively as a structural pipe. A53 line pipe is essential for extracting liquid from the ground in the gas and oil industries in particular.

A53 steel pipe can be utilized for mechanical and pressure purposes, notably when moving gas, oil, steam, or air. This pipe may also be found in wind turbines, anti-static tubes, machining components, underground water drilling, and boiler water transfer. It can be welded, coiled, shaped, bent, or flanged under specific circumstances.

With one exception—welded steel cannot be flanged—A53 steel is appropriate for welding operations including bending, coiling, and flanging.

ASTM C127 Obtain Specific Gravity and Absorption of Coarse Aggregate